HOME > Sinto original technologies

Sinto original technologies

Immersion V process

In the ceramics manufacturing process, upsizing, free shaping and cost reduction of ceramics have been achieved using our original vacuum molding technologies. They are not conventional CIP or plaster die casting processes.

Super-precision machining

The super-precision surface polishing machine has achieved a straightness of 1.0 μm/m or less and a flatness of 1.0 μm/m or less with structural ceramics longer than 2 m.

Slurrying of high-purity alumina material

Integral molding by immersion V process

Firing in a large-size gas furnace that can accurately control the burning program.

Super-precision machining by surface polishing machine and machining center

Various inspections by 3D measuring instrument.

Integral production covering large-size integral molding exceeding 4 m and super-precision processing to inspection. We bring new values to manufacturing sites.

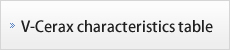

Features of V-Cerax