HOME > Product > Product lineup > Structural ceramic components

Structural ceramic components

Sinto’s “V-Cerax” ceramic is adopted in all fields, including semiconductor and LCD fields, as a component for super-precision and high-precision measurement and inspection devices. V-Cerax is highly reliable and has been upsized by our original “Immersion V-process”, which has earned high evaluations and trust from customers. It continues to be selected because of it's compatibility with complex shapes.

Slip casting by Sinto’s original “immersion V-process” produces structural ceramics that have never been achieved by conventional CIP or plaster die casting processes.

Features

-

Applicable for manufacturing large-size products exceeding 4 m.

V-Cerax enables the manufacture of large-size components with micron order precision. -

Short delivery time

V-Cerax can meet requests for large-size products because it is produced entirely in house from molding and firing to processing. -

Applicable to complicated shapes. High degree of design freedom.

Near-net-shape forming is possible even for casing boards, square boards, long-size boards, disks, rings, and other large-size products. -

No expensive mold needed

Our original technologies require no mold such as rubber molds and plaster molds.

*This varies according to component. -

Readily suited to wide-variety small-lot production. Low cost production.

V-Cerax easily enables wide-variety small-lot production from a single prototype to mass-production. This results in cost reduction. -

Applicable for mirror-finishing

Ceramics components can be given a mirror-like finish. -

Performance can be improved by replacing existing structural components with V-Cerax.

(High accuracy, high rigidity, heat resistance, abrasion resistance, corrosion resistance, etc.) -

Compatible with various materials.

Alumina, aluminum titanate, zirconia, aluminum nitride, silicon carbide, silicon nitride

Consult Sinto for development and design.

We support customers in the development and design stages who are investigating the adoption of ceramics.

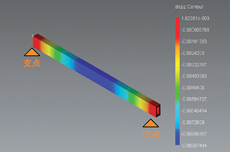

we carry out “thermal stress analyses,” “mechanical stress analyses,” and other simulations based on the assumed conditions of use, and propose the optimum ceramic specifications.

We deliver products via an integrated production system from material adjustment to finishing.

Sinto's structural ceramics provide a lot of advantages to customers -- high quality, small products to large products, high degree of freedom in shaping and sizing, low cost, and super short delivery time.

Frequently asked questions

Q: May we ask for just a quote?

A: Of course. Please feel free to contact us.

Q: We do not have any drawings. Could we contact you?

A: We are ready to support you from design and drafting. We can design and draft technical drawings for you. In such event, you need to provide us with reference data, sketches, or anything that could project your image.

Q: We want to renew the existing structure, but we do not have any drawings and other data. Are you able to meet our request?

A: If no drawings or data are available, we will conduct a field survey and create the drawings. Don’t hesitate to contact us.

Q: We want to change materials if better materials are available.

A: If we could receive details of the product (strength, heat resistance, or other conditions), we will propose materials that fit the product. Please feel free to contact us.

Q: We want to learn whether ceramics are suited to our product or not.

A: We will ask you about your application conditions and other details, and make the best proposal to you.

Q: We are thinking of a complicated shape. Could you take care of it?

A: We have a wide variety of examples of actual products. We are sure that we can make a proposal that best satisfies your requirements. Do call us immediately.

Q: Is it possible to coat ceramics?

A: Coating is possible, however coloring is not possible because of product characteristics.

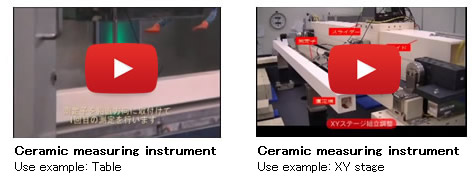

Case examples

You can see the case examples in animation, too. Click the picture below. (You will be sent to You Tube.)

Structural ceramic component examples

We satisfy customer requirements for product size and working accuracy, not to mention ceramic components such as ceramic vacuum chucks, etc., for which the difficulty level is generally said to be high. Please feel free to ask us anything from questions concerning sizes and shapes to quotations.

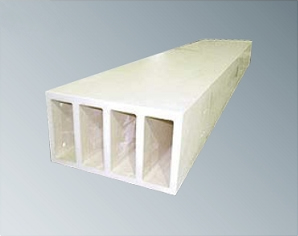

Inspection device guide shaft (hollow)

Compared to stone and metal, structural ceramics are lightweight and highly rigid and, therefore, small deflection under its own weight.

1700mm

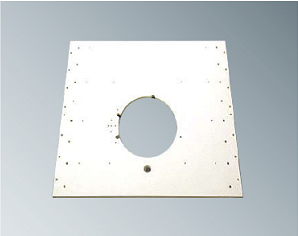

Stage surface plate

Owing to “2 μm flatness”, which is impossible with metal, high accuracy measurement and working are achieved.

□900 m; Flatness: 2μm

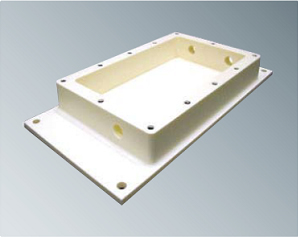

Vacuum chamber component

Because of their electric insulation and high heat resistance, ceramics can be used for wall surfaces of vacuum chambers.

Inspection device components

Best suited for components where high accuracy and high rigidity are essential.

We can provide sizes that satisfy customer requirements. Feel free to contact us with your size requirements including desired delivery time, etc.